Petersen Stainless Rigging Ltd

Petersen Stainless Rigging Ltd

CE Certified Swaging System to EN 13411-8

The Petersen swaging system complies with EN 13411-8 and has been tested accordingly. This European standard specifies the minimum requirements for swaged terminals and the securing of such terminals by a swaging process to wire rope conforming to EN 12385-4 and EN12385-5, spiral strand rope conforming to EN12385-10 and stainless steel stranded rope. This European standard is applicable to swage terminations with a terminal efficiency factor of at least 90% and are used as part of a wire rope accessory such as a sling, or wire rope assembly that performs a raising, lowering, holding or supporting function on lifting machinery.

Swage terminals will be supplied marked 'CE' and with a unique batch traceability code. All swage terminals are supplied with instructions for the correct fitting and safe useage.

Petersen swage sockets and crane rope buttons are manufactured in the UK from high quality European steel. The Petersen quality system is ISO9001 and aerospace AS9100 certified giving full traceability on all swaged lifting sockets. Raw material certificates are available on request.

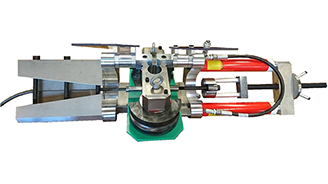

The Petersen swaging and testing machine is required for the correct pressing of the terminals onto the wire rope. After securing the terminal, the wire rope can be gripped and a proof-load applied, all on the same machine. The convenient design means proof load tests can be carried out on lifting assemblies without the need for external equipment. The comparatively low weight and compact design of the Petersen swaging and testing machine means assembly and testing can be done on site. For example, using this equipment it is possible to re-terminate and proof-load test a crane rope which is still attached to the crane, at the worksite. This revolutionary system offers enormous savings to mobile and tower crane service companies by minimising down time due to rope inspection and repair.

Please contact one of our sales team to learn how Petersen can help your business.